What is not “automatic” is “manual.” Opening the doors of the greenhouse, we ourselves - and the temperature sensor (or the analyzer - if there is a thermometer), and the drive ...

Gardener is the most sensitive and reliable "mechanism". "Cons" - non-stationarity, the desire to work in multitasking mode, combined with a limited number of hands.

Automatic machine for airing greenhouses

In greenhouses and greenhouses shift to automatics the obligation to maintain a microclimate in the normal need:

- to save the strength of a gardener who has other concerns besides supplying the greenhouse with the necessary volume of outdoor air;

- to be able to leave the garden plot (to a city dweller):

- contain several greenhouses and everything to be in time (farmer).

"Forced" ventilation

When discussing the ventilation of the greenhouse, they talk about vents, because where there is a temperature difference on the same level, forced ventilation should not be required.

When discussing the ventilation of the greenhouse, they talk about vents, because where there is a temperature difference on the same level, forced ventilation should not be required.

However, there is another microclimate parameter, more inertial - humidity. With its redundancy at normal temperature in the greenhouse will help to cope fan.

The second reason to use it - greenhouse design features: lack of vents, their failure or unsuccessful location. Since the door to the greenhouse is exactly there, it is opened slightly, and the fan mixes the internal air, and it cools (or does not heat up) in all zones of the volume equally.

Turn on the fan in the absence of a gardener will be able to thermal switch.

Features of systems of recirculation fan + thermal relay

Merits:

- Easy to manage.

- May have more power.

- Compact.

- Maneuverable.

- Modifiable (it is possible to complicate the system, including additional elements in the chain).

Disadvantages refers to the so-called volatility. A backup power supply is required in case of power failure.

Natural airing

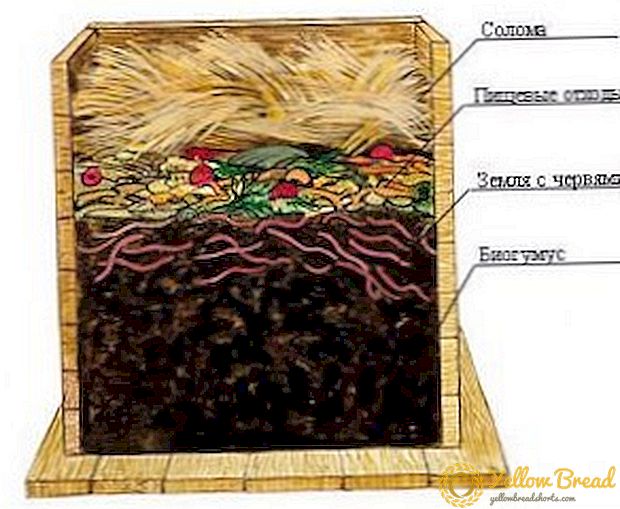

To create a "thrust" Apertures in the roof are often arranged on two levels: above the floor (if the plants on the shelves are slightly higher than the shelves) and close to the ridge (or the zenith of the arch).

But the retention of microclimate parameters within acceptable limits is ensured by the timely commencement and cessation of ventilation, as well as by its intensity (that is, the width of the opening of the valves).

Device types

Consider what are the types of machines for greenhouses for ventilation.

By autonomy

- Elements having in their design, the physical characteristics of which, when heated from ambient air, change so much that they are capable of performing considerable mechanical work.

- Responding to temperature sensor readings.

By type of drive

Hydraulic

The mechanism converts the force of fluid pressure into mechanical work. Hand-made - a visual aid in physics for the student.

The mechanism converts the force of fluid pressure into mechanical work. Hand-made - a visual aid in physics for the student.

Power supply - potential energy of the working fluid (the mechanism is non-volatile).

The simplest and, at the same time, hand-made version of the execution - yoke, at the ends of which is fixed on one container with liquid, interconnected by a hose. Inside the system "capacity-1 - hose-capacity-2" the law of conservation of energy works. The pressure in the system tends to be the same throughout its volume.

Process starts pressure difference inside tanks. Since one end of the rocker in the greenhouse, the other - outside, they heat up differently. The working medium is shifted to the colder side, that is, into the outer cylinder; the outer end of the rocker arm under its weight lowers and pulls the flap of the window leaf behind it.

On sale hydraulic mechanism with one cylinder (aluminum or steel). The machine is located entirely inside the greenhouse. In the cylinder: oil, piston, rod, seals. In the simplest modification, the free end of the stem rests against the transom and is attached to it.

The fluid expands, pushes the piston, and the rod pushes the door out. At the return stroke of the piston the rod will pull on itself (more slowly, but will pull). Between the rod and the window sometimes arrange additional elements (levers, springs).

Unprotected from direct sunlight the oil cylinder will heat up from them, and not from the air in the greenhouse.

The peculiarity of this particular design

External mechanical pressure on the vent may spoil such a hydraulic drive. Therefore, in addition to the sunscreen, the system is supplemented with clamps of the maximum position of the door: with cables, ropes or tapes. They contact only with the frame and transom.

Selection

Hydraulic automatic greenhouse ventilators differ:

- weight of the opening web;

- piston stroke (and the angle of change of the position of the blade);

- the material of the cylinder and the presence of clutches;

- dimensions, shape of the section and material of the rod, as well as levers.

Customization

The trigger threshold is chosen by a special nut in the range proposed by the manufacturer.

Merits

- Reliability.

- Simplicity of design.

- Big power.

disadvantages

- Productive tandem forms only with horizontal vents.

- Anxiety (any liquid cools much longer than it heats up; with a cold snap, the air in the greenhouse may have time to cool down).

- There are restrictions on the maximum operating temperature.

Examples of models

Automatic machine for airing greenhouses Belarusian production will start opening the door no heavier than 7 kg at a temperature chosen by the owner in the range of 15-25 ° C. Finish the job at a 30-degree internal heat.

Identical domestic machine differs by the possibility of partial detachment from the sash without dismantling, which allows you to open the vent widely by hand.

Manufacturer of the Republic of Bashkortostan declares the maximum force of the rod 100 kg for one of its thermal and 125 - for another.

Electric for natural ventilation (drive with motor)

Gardeners make such designs yourself, using actuators from satellite antennas, motor-reducer from car heating stove, etc.

Are they on sale?

For example, “Linear Drive” domestic (12V / 3A) with a gear motor and “Radial” (gear - rack gear) in just 5 seconds promising to open the door 140 °, work complete with a control unit (220V / 4A). One unit is required for 4 linear or 2 radial drives.

Are good large opening angle of the ventilation opening.

Minus - dependence on notorious power outages - volatility.

Bimetallic

- Fully autonomous.

- Cheap and simple.

- Non-volatile.

disadvantages

- Small power (reinforce it by sequential arrangement of several pushers).

Design

Sensitive element - plate of two metals (for example, brass-steel). She's a pusher.

Sensitive element - plate of two metals (for example, brass-steel). She's a pusher.

The plate changes shape in response to changes in indoor temperature. Being connected with the door, pushing it or pulling it towards itself (like an unfixed end of a bimetallic tape in a thermometer, it moves the dial on the dial).

The essence in that both metals, heating up equally, their linear dimensions will change differently. (Brass will increase by 1.4 times stronger steel, copper - by 1.3). The bimetallic plate is bent in the direction of a layer of metal with a large coefficient of temperature linear expansion.

The same effect underlies the operation of elements that automatically close an electrical circuit.

With independent production You can take a composite material (usually steel), and you can mechanically connect two plates with rivets or bolts.Two different materials are also combined: for example, a galvanized iron plate no thicker than 1 mm is attached to plexiglass up to a centimeter thick.

The larger the greenhouse, the more self-opening vents you need to control the temperature. It is good if the total area of ventilation openings is a quarter of the roof surface of the greenhouse.

Successful location frequency automatic air vents for the greenhouse - 1 to 2-3 meters in length.

The elongated shape requires an additional — longitudinal — flow. It will create two vents in the ends, one opposite the other.

Efficient natural air circulation allows you to maintain optimal values of temperature and humidity inside the greenhouse in any weather.

And here are videos about the design of the automatic ventilation system of the greenhouse, the mechanism for opening the vents in the greenhouse on temperature (pusher, opener-automatic, other devices and their device).