Nowadays, on almost every private land plot you can see such a very familiar and widespread device as a greenhouse, which is intended for the cultivation of various plant crops.

They are mainly used for growing vegetables, but often they are planted in berries and flowers. There are several types of greenhouses, differing from each other in size, shape and performance characteristics.

One of the varieties is collapsible greenhouse.

Description

To date, collapsible greenhouses have become quite popular due to its mobility and practicality in operation. They are convenient in that they can be easily moved from one place to another.

It is possible to make the simplest collapsible greenhouse do it yourself. Such a task will not be difficult, because it does not require special skills, as well as the presence of any additional tools. Moreover, the construction of such a device requires only a small investment of money.

It is only necessary to have patience and effort. Folding greenhouses are considered more convenient.Despite the rather complex structure, they are built relatively quickly and easily.

Features of the installation of collapsible greenhouses

Collapsible greenhouses have a number of different benefitswhich include the following:

- Total absence of wind, and also drafts dangerous for plants.

- The presence of favorable lighting.

- The soil, like the air, heats up more strongly, which ensures the absence of temperature fluctuations inside the greenhouse.

- Reliable protection against a variety of plant pests.

In order to build a collapsible greenhouse with your own hands, you need to find the most important part of this design - it is special plastic knotwhich has four ends and as many holes with a diameter of 10 mm.

These holes need to be securely fastened pipestaken from a split folding bed - they can easily penetrate into the nodes. Such installation technique allows not only to give lightweight construction to a greenhouse, but also to significantly increase its operational life.

After the stands and racks are built from the knots and clamshells, you should proceed to the work of the second stage.

The main task is in the proper manufacture of all necessary veins. To obtain these parts, you need to take rails, 1 m high and about 3-4 cm long, and their width should be about 4-5 cm.

Just like the pipes that were taken from the clamshell, they are carefully drilled to make holes with a small diameter.

Loanwhich will be made of copper pipe, should be cut into small pieces, and then these cuts are firmly inserted into the rail with a sufficiently strong fit. Such an operation is the final and final step of building a complete structure for a collapsible greenhouse.

In cases where as cover plastic film was chosen, this material must be secured on two opposite sides to the structure with the help of ordinary plastic bottles filled with water, which will be able to press the film.

Such an event will help ensure the continued protection of the future crop of vegetables from strong gusts of wind.

Folding greenhouses under the film on a private plot of land in appearance is almost not similar to the well-known greenhouse. They are more like a standard shelter, which is characterized by a simple form, this is especially reminiscent if you use plastic wrap to cover.

To date, cottages, in areas of which there is such a structure, are not considered modern. This is explained by the fact that the uncomplicated construction looks rather outdated, because nowadays there is a huge variety of significantly improved devices specifically for the garden.

This technology has been around for about thirty-five years, but many people still like it.

Folding and team greenhouse very easy to useAfter all, if the need arises, it can be moved to any more suitable place. In addition, these greenhouses are very mobile - at will the design can be completely disassembled, and then hidden in the corner of the garage or shed.

What are the advantages of polycarbonate?

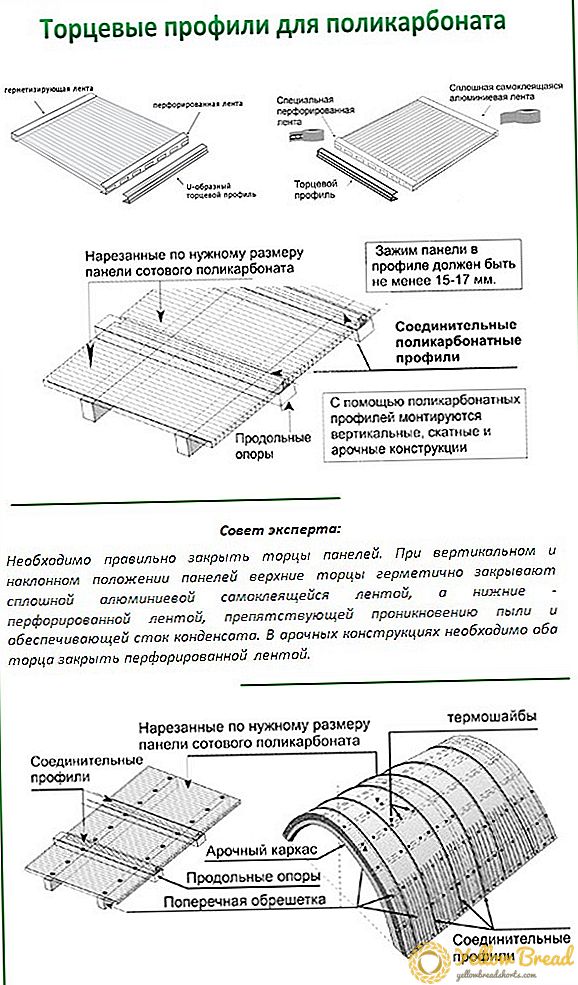

Polycarbonate is considered one of the newest and highest quality technologies.

This material is unique. It is lightweight, durable and has a long service life. is he has the following properties:

- Excellent noise isolation.

- The material transmits light in large quantities.

- Reliable heat insulation.

- Does not react with various chemically active substances.

- Fireproof.

- Elasticity persists over a long period of time.

- Does not give in to destructive influence of external factors.

He managed to force out glass and film in the building materials market. Glass is a more dangerous material to use. Structures made of polycarbonate, it is very difficult to break into pieces, and the glass is quite possible, after which one should not exclude the possibility of injuries or injuries to the hands and even the legs in the process of cleaning fragments.

In addition, glass is a heavier material, which, of course, cannot be said about the design of polycarbonate.

Products made using polycarbonate characterized by excellent insulating effect.

Because of the whole features characteristic of polycarbonate, very favorable conditions are created for the rapid growth of plants, a significant improvement in their condition and an increase in size.

Thanks to the dense walls, which are made of durable polycarbonate, constant mitigation of translational direct sunlight, as a result of which the absence of the need for additional darkening is guaranteed.

In the final stage installation of a collapsible polycarbonate greenhouse, namely the coating of its basic structure, polycarbonate sheets are securely fixed to the clamshell pipes.

The latter have some properties that allow the material to take on virtually any shape, because they are quite flexible enough, which is a huge advantage in their application.

Metal carcass

There are also prefabricated greenhouses on a metal frame. They have a more modern look, so they are considered a more suitable option for arranging a summer cottage.

There are also prefabricated greenhouses on a metal frame. They have a more modern look, so they are considered a more suitable option for arranging a summer cottage.

Such structures are already stationary construction, but with the proper creation of a sketch, it can be turned into a collapsible structure.

This solid construction will be perfectly suited for operation over a long period of time.

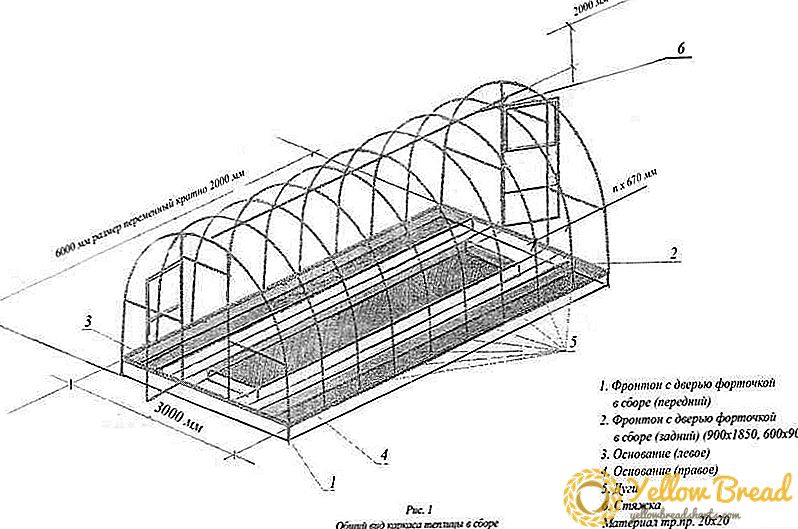

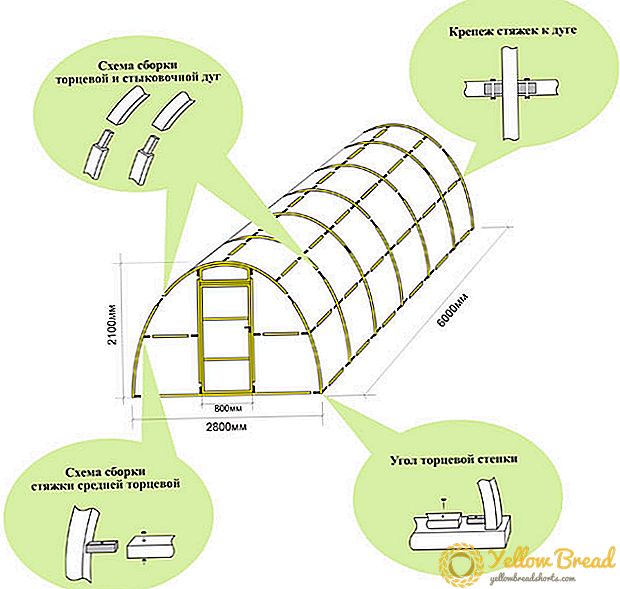

The basic principles of the installation of the frame, and also stages of installation of the greenhouse folding type:

- It is necessary to choose the right area of the site.

- The dimensions of the greenhouse construction are determined in advance.

- Sketches of the future greenhouse are made.

- A metal greenhouse is being made.

- The long side of the greenhouse must always be located in the direction from east to west.

- Metal structures should be located on a clean and well-lit area.

- The design is mounted according to the scheme prepared in advance.

That is why more experienced users recommend choosing exclusively high-quality materials for their construction.for plants to get the most nutrients they need for growth and development.