"Small mechanization" in the face of the motoblock is indispensable for the owners of large gardens. There are many brands and models on the market that differ in their design — even units that look alike may require different parts for repairs.

"Small mechanization" in the face of the motoblock is indispensable for the owners of large gardens. There are many brands and models on the market that differ in their design — even units that look alike may require different parts for repairs.

Therefore, many people buy domestic products, the good, the details on them in abundance. Consider one of these units - the popular "Cascade" tiller, at the same time having learned the exact technical characteristics of its varieties.

- Description, modification, specifications

- With DM 1 engine

- With Briggs & Stratton INTEK Engine

- MB 61-21

- MB 61-22

- MB 6-06

- MB 6-08

- Features of operation

- Running in after purchase

- Care and work with walk-behind tractor

- Attachment Features

- Basic problems and service manual

- Problems in the carburetor

- Gearbox faults

- Insufficient power

Description, modification, specifications

This model is built according to the classical scheme using four main groups of nodes - power unit, transmission, chassis and controls.

About motors talk later. The fact is that any of a whole series of “engines” can be installed on a walk-behind tractor, and each of them is designed for a separate modification.

Transmission, in turn, consists of a clutch, a chain or gear reducer and a four-mode gearbox (two steps forward and back). All these nodes can be assembled in a block or placed separately.

Running gear favorably with the fact that you can adjust the width of the track, exposing the desired value. Otherwise, everything is familiar - a rigid frame with mechanisms "packed" in it and a fixed axis. As for the wheels, they can be either pneumatic, with high hooks, or rigid metal.

Control It is carried out by a wheel of motorcycle type with the throttle, clutch, power take-off and start levers placed on the handle. Transmissions are also switched by a lever located slightly below.The steering wheel itself is easily adjusted in height, which facilitates the work.

As you can see, everything is familiar and quite thought out. Now let's take a closer look at the modifications that have been mastered a lot over the years of release, and find out how they differ.

Note that the dimensions of all manufactured "Cascades" are almost the same, which cannot be said about the motors. The number in the index indicates the type of engine: 61 denotes an import unit, while 6 indicates a domestic one. The numbers following them represent the purpose of the mechanism and the version.

With DM 1 engine

The domestic engine is considered the base for the Kaskad motor-block - many copies are equipped with this particular motor.

This is a single-cylinder four-stroke engine, which develops 6 liters. with. with a torque of 14 N / m. It has more volume than imported ones - 317 cm cube. with a dry weight of 28 kg. Other characteristics of the block look like this:

- Coupling - belt;

- Gearbox - gear;

- Capture depth (mm): - 300;

- Plowing width (mm) - 930;

- Fuel - AI-80, AI-92, AI-92;

- The volume of the tank (l) - 4, 5;

- Fuel consumption (l / h) - no more than 2;

- Dimensions (mm) - 1500 × 600 × 1150;

- Weight (kg) - 105.

With Briggs & Stratton INTEK Engine

This American "air vent" is distinguished by its reliability and build quality.

- Working volume (see cube) - 206;

- Power (l. S) - 6.5;

- The diameter of the cylinder (mm) - 68;

- Torque (N / m) - 12.6;

- Dry weight of the motor (kg) - 15.3;

- Fuel - AI-92 and AI-95

- The volume of the tank (l) - 3.6;

- Fuel consumption (l / h) - in the range of 1.6-1.8.

MB 61-12 On the "twelfth" it is used American installations. Because of this, their price is higher, which discourages some farmers.  This line includes ten modifications. All of them have a belt clutch and chain gear.

This line includes ten modifications. All of them have a belt clutch and chain gear.

But their working parameters:

- Capture depth (mm) - up to 260;

- Plowing width (mm) - modes 450, 600 and 950 are provided;

- Speed (km / h) - up to 13.

Having seen a long row of numbers after the MB 61-12 designation, keep in mind that the numbers shown in the dash "give out" the following nuances of the device:

- reinforced gearbox (02);

- basic gearbox (04). In such instances, the output shaft is "seated" on the needle bearing, on all other modifications there are usual ball clips;

- reinforced gearbox with an increased speed range (05) and unlocking wheels (06);

- cars with automatic unlocking of wheels and a reinforced gear "pass" under the symbol 07.

With the “tail” numbers, everything is simple - “01” always points to the usual steering column, while “02” always indicates the steering column. All these data not only allow you to find out the technical characteristics of any Kaskad motor-block, but also select the necessary spare parts.  These indexes are universal, that is, they apply to all products with this name, regardless of the type of engine.

These indexes are universal, that is, they apply to all products with this name, regardless of the type of engine.

MB 61-21

Variation with the Japanese motor Robin-Subaru EX-21. It is easy to distinguish it even visually - the cylinder is located at an angle.

- Working capacity (cm cubic) - 211;

- Power (HP) - 7;

- The diameter of the cylinder (mm) - 67;

- Torque (N / m) - 13.9;

- Dry weight of the motor (kg) - 16;

- Fuel - AI-92 and AI-95

- The volume of the tank (l) - 3.6;

- Fuel consumption (l / h) - up to 1.85 l.

The starter is represented by the usual cord, but the ignition is on the transistor inductor. Coupling - belt. The electrical system has a built-in "permanent" generator.  Other features:

Other features:

- Capture depth (mm) - from 100 to 200;

- Plowing width (mm) - up to 900;

- Speed (km / h) - up to 13;

- Weight (kg) - 105.

MB 61-22

Here, the professional Honda GX-200 motor acts as the “heart”. Among the arguments in his favor - the highest quality of fit and assembly, good efficiency and resource details. Minus, perhaps, only one - the high price.

- Displacement (cm3) - 196;

- Power (HP) -6.5-7;

- The diameter of the cylinder (mm) -68;

- Torque (N / m) -13.2;

- Dry weight of the motor (kg) -16;

- Fuel-AI-92 and AI-95

- The volume of the tank (l) -3.1;

- Fuel consumption (l / h) to 1.7 liters.

As a result, achieved such performance indicators:

- The depth of capture (mm) -to 320;

- Plowing width (mm) -450-930;

- Speed (km / h) - up to 12 when moving forward, 4 for reverse;

- Weight (kg) - 105.

MB 6-06

Modification with the domestic motor DM-66.In fact, this is the same DM-1 - the characteristics are identical, except that the "sixty-sixth" is 3 kg lighter (dry weight is 25 kg). An oil sprinkler is integrated into the lubrication system.

- Capture depth (mm) - up to 320;

- Plowing width (mm) - two modes are set (for 350 or 610);

- Speed (km / h) - up to 10;

- Weight (kg) -105.

MB 6-08

The engine model DM-68 virtually duplicates the power unit of the "sixth" series. But there is a smaller tank, and the oil is forced into the parts through the unit.

- Capture depth (mm) - up to 300;

- Plowing width (mm) -450, 600 or 900

- Speed (km / h) - up to 10.3;

- Weight (kg) - 103.

Features of operation

Having decided on the choice and having bought the suitable motor-block, do not forget about the rules of competent operation of such equipment. This will save on repairs and consumables.

Running in after purchase

The first hours and days of work are of utmost importance - the parts are only rubbed in, so they start with gentle loads.

Even before it starts, check all the fasteners, if necessary, tighten the weakest ones. The instruction manual for any Cascade series tiller prescribes a 35-hour run-in cycle. During this period it is recommended:

- warm up the motor for 3-5 minutes without load, setting the average speed;

- work only in first gear at medium speeds. Small turns are always the risk of overheating. Maximum so far is contraindicated;

- after the first 5 hours the oil should be replaced;

- until the end of the run-in, it is necessary to lay a new batch at intervals of not more than 7 hours (and preferably after 5);

- After 35 hours, the oil changes, all connections must be inspected, if necessary, tighten loose bolts.

Immediately upon completion of the run-in, they try not to give the motor a full load. This is done gradually so that, at first, maximum modes accounted for no more than 25% of the total working time.Many owners adhere to this rule a couple of months after the plant has been set aside for lapping.

Immediately upon completion of the run-in, they try not to give the motor a full load. This is done gradually so that, at first, maximum modes accounted for no more than 25% of the total working time.Many owners adhere to this rule a couple of months after the plant has been set aside for lapping.Care and work with walk-behind tractor

Line inspections and maintenance are reduced to such procedures:

- daily removal of dirt, dust and oil from all exterior surfaces;

- frequent checking of available mounts. Broach - as necessary;

- visual assessment of the condition of the belt. Bundles are not allowed;

- check attachment attachments;

- every 50 hours, the belt tension and all fasteners are thoroughly checked, and the oil in the gearbox is changed.

To change the belt, you need to know its size and marking, because only the products designed for it will fit into the Cascade walk-behind tractor. These are products with indices A1180 (forward) and A1400 (for the rear).

The letter "A" denotes a profile in 13 mm. Often in the course are imported components, similar in size, but with internal teeth.

Naturally, the operating mode of the power unit must be adequate, without overloading and processing. Carefully read the factory documents - it shows all the necessary intervals and tolerances, which is better to adhere to. If this is not done, there is a risk of "ruining" an expensive motor.

Getting to work, the driver makes the wheel more comfortable and keeps the motoblock parallel to the ground. The slightest bias - and the car just "closes." The maximum depth of cultivation in a single pass is 200 mm (on soft soils). In more difficult areas it is reduced to 100-150 mm.

Another nuance - stony ground is passed only in first gear, so as not to break the knives.

At the end of the season, the unit is placed in a dry ventilated area. It can be stored on the street, under a canopy, having previously covered it with a cover made of tarpaulin or polyethylene. Before this, make sure that the engine and gas stop levers are in the STOP position.

For preservation, all unpainted parts are treated with oil type K17. The duration of such storage is one year. If the motoblock has stood motionless longer, the lubricant is put in again, after which they do not forget to tightly “wrap up” the mechanism.

Attachment Features

The standard set includes such devices:

- 4 mills of different depth for loosening in different modes;

- grouser extension that improves throughput;

- coulter cutting soil.

"Functionality" can be significantly expanded by purchasing a set of additional equipment. Among the most popular devices stand out:

- hillerswhich are indispensable when working with plantations of root crops. They allow you to make smooth "ridges" on large areas. They are "permanent" and adjustable;

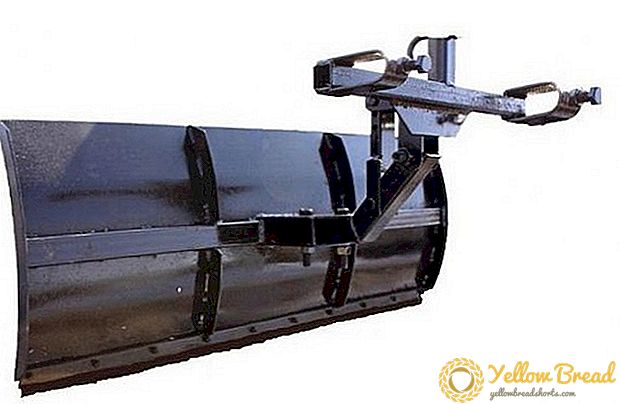

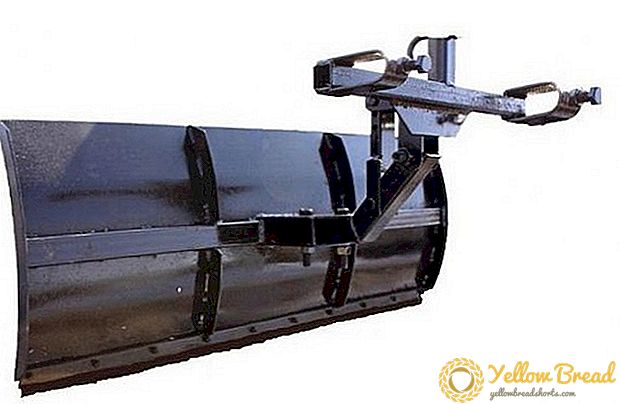

- shovel blade, facilitating excavation and garbage collection (and in the winter and snow);

- plows with different width of the plowshare;

- flat cutsremoving weeds between rows;

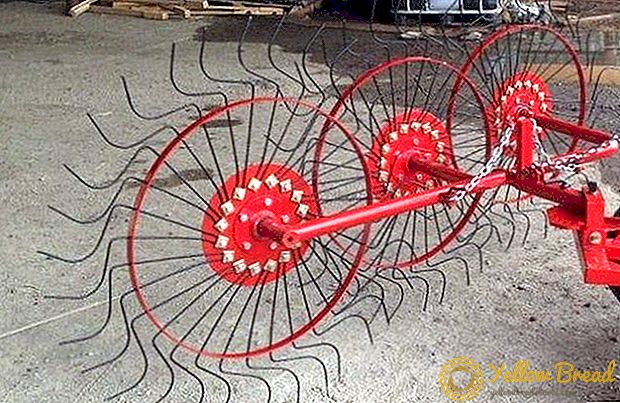

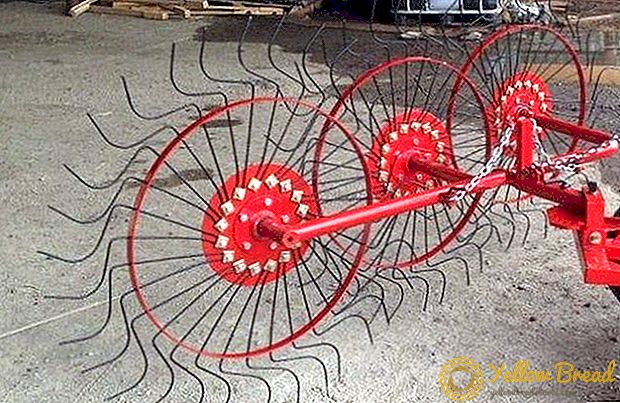

- rake;

- stand alone trailerswhich can easily take one and a half to two centners of cargo.

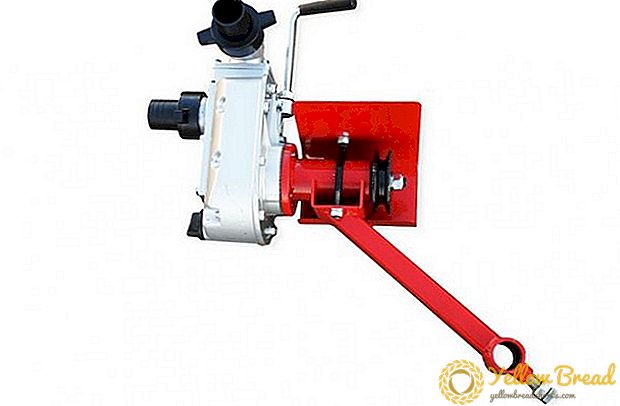

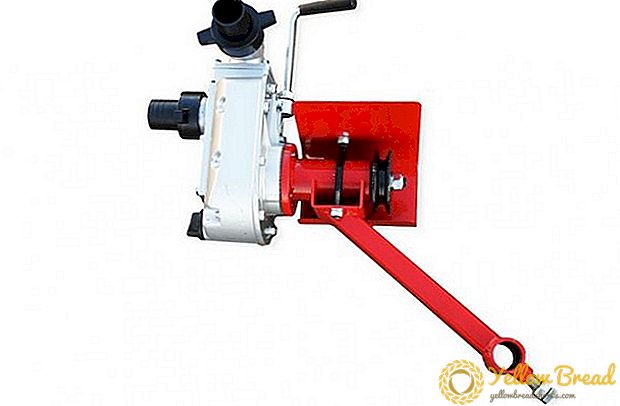

"Cascade" works confidently with drive units that are connected by an additional belt:

- mowing;

You will probably be interested to learn how to make a mowing machine for the motoblock with your own hands.

You will probably be interested to learn how to make a mowing machine for the motoblock with your own hands. - snow blower;

- water pump;

- potato planter

Familiarize with the main types of potato for motoblock.

Familiarize with the main types of potato for motoblock.

Basic problems and service manual

Any farmer can easily name several "family diseases" of motor-blocks. Usually they relate to the power system, belts and transmissions.

The insidiousness of such breaks is that they can manifest themselves even with proper care - low-quality parts or fuel are involved in the matter (whereas flaws in the assembly are quite rare). Let's stop on the most widespread problems and methods of their elimination.

Problems in the carburetor

They are familiar to all motorcyclists, and for a person with experience do not represent a problem. Although it will understand and neat newcomer.

Let's start with the simplest - the fuel does not enter the carburetor. To verify this, you have to unscrew the candle - a dry one will confirm such a hunch. The actions will be as follows:

- having filled the tank, open the fuel valve;

- then clean the hole in the bottom of the gas tank - the initial drainage can be complicated;

- if the gasoline never reached, you will have to drain it from the tank, remove the faucet and flush it;

- then unhook the hose from the carburetor body. It is blown along with the jets. After re-mounting the crane, everything will work as required.

It seems to be simple, but in the field it’s not a pleasant job, and the wind can put dust in the jets.

It seems to be simple, but in the field it’s not a pleasant job, and the wind can put dust in the jets.More complex situations (for example, when fuel does not enter the cylinder) will require the dismantling of the carburetor and its further bulkhead.

In this regard, the Kaskad tiller unit compares favorably with imported cars, and factory repair instructions describe the process in all its details. In general, it looks like this:

- An already removed unit without gasoline residues is blown through with a choke, while trying to keep it in a position close to the worker. A simple test - if you turn it up, the air should not pass.

- making sure of this, adjust the tongue in the float chamber. It must be carefully bent or bent to ensure normal circulation;

- the next step will be the control purge of the jet;

- at the end, the engine is warm at low speed (no load). Focus on the sound, if necessary, slightly loosening the twisted screw "gas".

These are typical "failures" of the power system, which account for a large proportion of equipment downtime.

Gearbox faults

Late oil change and violation of the operating mode lead to breakage of one of the main components - the gearbox. Most often, this element of the transmission annoys such difficulties:

- the displacement of the sleeves from the chain, causing it to loose and can go. This is the result of large lateral loads;

- accelerated wear of the bearing washer, to which the regular operation of the block at an angle to the ground brings;

- the collapse of the sleeves, which is fraught with a chain. Often a dangerous crack becomes the result of "rationalization" when more powerful homemade mills are put on which the motor is not designed.

- epiploon leakage, which is easily eliminated (in comparison with a complete reassembly of the node).

It is easy to recognize the first signs of such violations - just listen to the working unit. If characteristic and clearly unnecessary "growls" appeared, accompanied by clear clicks, then it is time for repairs.

It should be noted that the gearbox of the well-groomed Cascade motoblock can only be disappointing with a "tired" stuffing box. And it changes like this:

- cutters are removed from the shaft;

- unscrewing the bolts, remove the protective cover (it may not be on the “second-hand” copies);

- the gland is removed by hooking with a needle or something similar;

- A new "gum" is wiped from dust, lubricated with engine oil and put in place. You can even besiege it with a socket wrench. Hammer it gently, to a slight stop. Done!

There are no difficulties, it will be easier to change the oil. But the installation of new bushings and chains will require skill - the gears must be strictly aligned, without shifting.

Insufficient power

For intensively working motor-blocks for 4-5 years of work, there is often another problem - after a normal start-up, the engine works unevenly, significantly losing power.

An experienced mechanic will immediately look at the color of the exhaust. Black color suggests: too rich mixture passes into the carburetor. If this node has recently moved, unscrew the candle. Abundant carbon deposits, coupled with an oily electrode, are observed with:

- clogged air filter;

- violation of the tightness of the fuel valve carburetor;

- worn oil scraper piston ring.

Changing the filter and adjusting the carburetor or valves is much easier than “poking” the engine to replace the rings. Such time-consuming operations are resorted to in another case - if the compression is broken.

In this case, only the rings can not do: it is possible that the inlet valve is broken. In addition to replacement, in the course of such work, carbon deposits are removed from the saddle of the cylinder block and working edges of the valves.  Being engaged in such a difficult repair, carefully inspect the pistons and cylinder mirror. Now you know the difference between the numerous modifications of the popular Cascade tiller. We hope this information will help you choose a reliable copy that will last for more than a decade. Have a good shopping!

Being engaged in such a difficult repair, carefully inspect the pistons and cylinder mirror. Now you know the difference between the numerous modifications of the popular Cascade tiller. We hope this information will help you choose a reliable copy that will last for more than a decade. Have a good shopping!