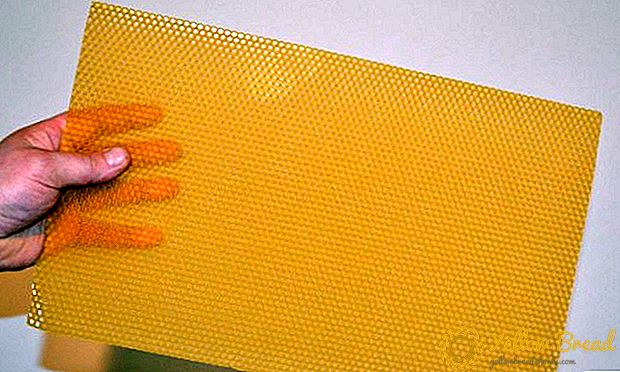

Voshchina - beeswax plates with extruded figures for quick building honeycombs. This sheet is fixed on a special frame that is installed in the hive. This design helps prevent the bee colony from swarming and fully load it. In short, the honeycomb is not only a guarantee of a good harvest, but also a guarantee of the health of the bee family. And is it possible to make a plate with his own hands at home, we will consider further.

Voshchina - beeswax plates with extruded figures for quick building honeycombs. This sheet is fixed on a special frame that is installed in the hive. This design helps prevent the bee colony from swarming and fully load it. In short, the honeycomb is not only a guarantee of a good harvest, but also a guarantee of the health of the bee family. And is it possible to make a plate with his own hands at home, we will consider further.

- What is it for?

- What is it made of?

- Natural

- Artificial

- Rules for choosing a mousta

- How to make a foundation with your own hands

- Necessary equipment

- Training

- Manufacturing

- Rules of storage

What is it for?

Natural waxing - honeycomb, which is used by bees to accumulate a layer of honey. Moreover, hardworking bees independently build such cells for future broods, drones and queens.  If the natural purpose of the honeycomb is understandable, then it is worth telling a little about their role in beekeeping, because they not only provide a comfortable life for the bees, but also greatly simplify the work of the beekeeper.

If the natural purpose of the honeycomb is understandable, then it is worth telling a little about their role in beekeeping, because they not only provide a comfortable life for the bees, but also greatly simplify the work of the beekeeper.

So, honeycomb for bees performs following functions:

- expands the bee's nest;

- promotes decent performance of bees;

- guarantees the normal formation of a bee swarm in the spring.

What is it made of?

The bees use honey and flower pollen to clean the cells. But people went a little further and changed the manufacturing technology.

Natural

As a rule, in the production of cells use plain wax. The ideal waxing is made from pure white wax, which melts freely and leaves no residue.

Honeycomb wax, of course, have their advantages. First, it is an environmentally friendly material. Secondly, such co-substitutes are convenient and easy to use. And thirdly, due to the plasticity with such a material it is comfortable to work, the wax has a low melting point.

Artificial

Today, there is a non-natural wax wax replacement - plastic. TO advantages such material include:

- longer service life;

- less care and financial expenses;

- practically not deformed (unlike the wax version);

- can be made by yourself.

In addition, plastic honeycombs are easier to store because they do not break or twist.

Despite its ease of use, a plastic co-substitute has certain limitations:

- Sheets must be regularly treated for parasites and various diseases (at least three times per season);

- Before installing in the hive, it is imperative to apply a small layer of wax;

- when damage is not subject to repair, need a complete replacement.

In addition, data on how artificial plates are perceived by bees is not enough. Yes, and artificial material is not always acceptable in beekeeping.

By and large, the use of plastic honeycombs is entirely justified.

Rules for choosing a mousta

Of course, the material for the honeycomb cells must be chosen correctly, because both the quality and quantity of the crop and the health of the bee colony depend on it.So, when choosing honeycombs you need to take into account such parameters:

- First of all, the material must be of high quality. This takes into account the tensile strength and dimensions of the cells.

- It is also important that the distance between the parallel sides of the cells be the same (5.3–5.45 mm).

- On the lumen of the plate should be transparent.

- The ideal plate size is 410x260 mm (for a multicase hive, 410x190 mm).

- The material should not be contaminated and foreign inclusions.

How to make a foundation with your own hands

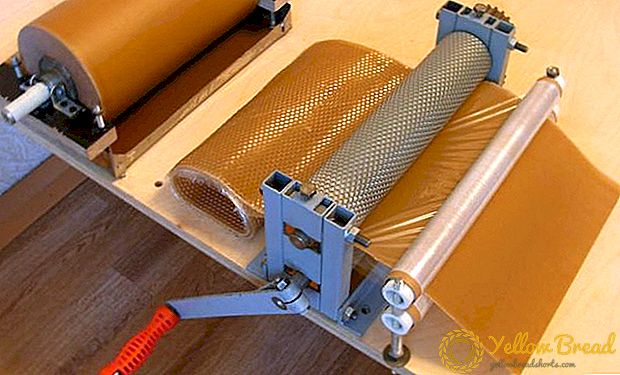

Few people can boast that they themselves make honeycombs. After all, they are manufactured on an industrial scale at the enterprises for the processing of wax material, and special machines for the production of wax are used. In this case, the wax melts and enters the rotating drum. After that, the molten mass is passed through a thin plate through rollers with an embossed pattern.

Necessary equipment

You can use several honeycomb devices:

- hand rollers;

- electric press.

Independently, the easiest way to make automated or manual rollers.

Independently, the easiest way to make automated or manual rollers.

First of all, you need to remember that the foundation should be of the highest quality and safe. Therefore, in its manufacture must adhere to such rules:

- Rollers and the working part of the equipment should be aluminum, with a thin layer of tin and nickel.

- For self-production of honeycombs, you can buy ready-made matrix.

- To save a cellular structure, it is advisable to purchase equipment with a cooling function.

- The unit must operate on the principle of the waffle iron.

Training

In order to prepare the honeycomb itself, it will take several subsidiary means: silicone and catalyst, which serves as a hardener.

You will also need a press or rollers for a flat with special impressions.

All parts of the equipment should be treated with linseed oil.

Manufacturing

In fact, the production of honeycombs is a simple process, but very attentive and scrupulous.

The first step is to clean the wax from impurities, boiling it several times in an enamelled vessel.

The wax after cleaning is melted in a water bath. After that, the sheet is removed to make the glass fluid, and spreads through the bath.

Then he warms up to improve the quality of the finished product. Further sheets scroll through the rolls, which gives them shape. So that the material does not stick to the rollers, the temperature of the rollers is reduced. This can be done by supplying cold water to the unit.

At the end of the sheets are dried in natural conditions.

Rules of storage

Store honeycombs in a dry place. It is better to keep the liner in thick paper and away from extraneous odors. At the same time, they try to prevent overheating of the material, since the wax melts easily, and the plates bend at the slightest heat. And the temperature below zero is undesirable.

Now you know more about the foundation, what it is, and even you can do it yourself, without serious financial investments, make substitutes and help your workers.