If you have a chainsaw at home, you should know that special care is needed for it. It is necessary to periodically clean and sharpen the chains, to clean the air filter, oil supply and tires. And, of course, you need to keep an eye on the chain tension, as with a bad tension there is a risk not only to harm the saw, but also to your health if the chain at high speed flies.

If you have a chainsaw at home, you should know that special care is needed for it. It is necessary to periodically clean and sharpen the chains, to clean the air filter, oil supply and tires. And, of course, you need to keep an eye on the chain tension, as with a bad tension there is a risk not only to harm the saw, but also to your health if the chain at high speed flies.

- Features of the device chainsaws

- Why chain flies, find out the reasons

- Bus problems

- Chain stretched

- Badly fixed leading sprocket

- How to stretch: setting the cutting element of the chainsaw

- Chain tension

- Stretch check

- Operation Tips

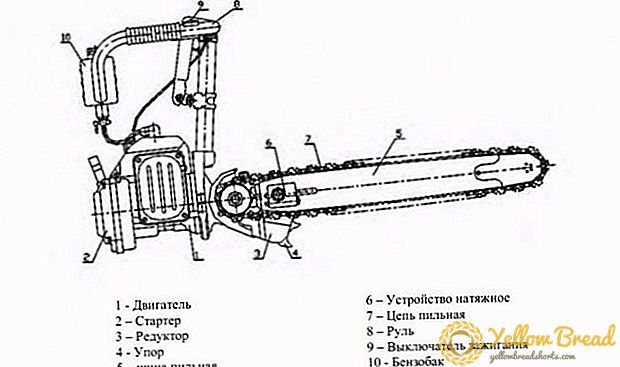

Features of the device chainsaws

The main part of the gasoline saw is engine. In most modern devices, the engine is single cylinder. Air cooling, two-stroke piston system.  Oil in these types of engines is added directly to gasoline, and all due to the fact that the fuel is constantly washed crankcase. The ratio of oil to gasoline varies from 1:20 to 1:50 depending on the manufacturer of the chainsaw.

Oil in these types of engines is added directly to gasoline, and all due to the fact that the fuel is constantly washed crankcase. The ratio of oil to gasoline varies from 1:20 to 1:50 depending on the manufacturer of the chainsaw.

Air filter on petrol saws plays an equally important role. He needs regular cleaning. If it is allowed to heavily contaminate the filter, the dust from it will fall directly into the piston system, which will lead to engine failure.

If the filter is clogged, the saw loses its momentum and the engine starts to overheat, and this can lead to burning of the piston rings.

The starter on gasoline saws is a rope with a handle, pulling which you are driving the motor. When you pull the rope, the teeth catch the ratchet, the flywheel starts to unwind.

The starter on gasoline saws is a rope with a handle, pulling which you are driving the motor. When you pull the rope, the teeth catch the ratchet, the flywheel starts to unwind.

Many complain that it takes a long time to pull the rope to start the engine. It depends on whether the carburetor is properly set. If the carburetor gives the correct mixture of oil and gasoline, then problems should not arise.

Main working mechanism - tire with tenacious.

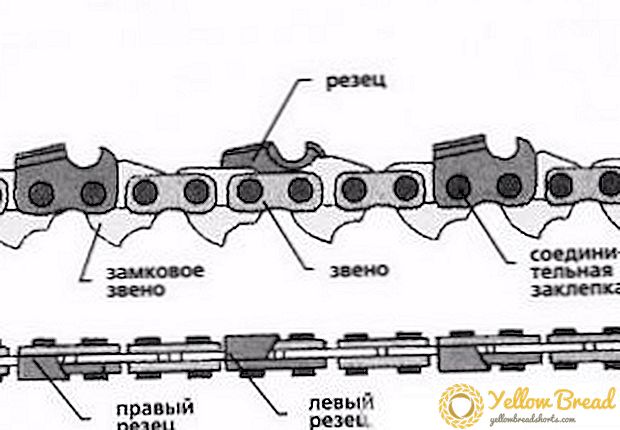

The chain consists of three types of teeth: leading, cutting and connecting. They are connected by rivets. The cutting teeth are located on two sides: right and left.

Chains are divided into two types: high-profile and low-profile. To the first type are chained, in which the teeth are arranged with a large gap, to the second - with a smaller gap. Also, the chains may vary in thickness of the shank and the length of the link.  Chainsaw chains attached to the tire, which sends it in the right direction. The end of the tire has a specific chute that holds the links and allows the chain to rotate. In front of the tire is a driven sprocket. The chain with the tire is called the headset, as they are removable parts of the chainsaw.

Chainsaw chains attached to the tire, which sends it in the right direction. The end of the tire has a specific chute that holds the links and allows the chain to rotate. In front of the tire is a driven sprocket. The chain with the tire is called the headset, as they are removable parts of the chainsaw.

The gasoline saw has an automatic chain lubrication system. The tire delivers oil, which sawdust then absorb. If the saw is idling, the oil supply is stopped.

Why chain flies, find out the reasons

If you wondered why the chain goes off on your chainsaw, then there are some problems in the mechanism. Exist three main reasons This problem: incorrect operation of the tire, stretching the chain and poorly fixed driven sprocket. Let us consider in more detail each of the possible causes of failure.

Bus problems

When problems arise with the tire almost always weakness stretch tenacious. Usually this problem occurs at the place of attachment of the tire.

This place is located in the groove between the outer plate, which is located on the casing of the chain headset and the inner plate located on the engine block. The casing together with the tire is fixed by a bolt. This mount is called the "engine knot." The drive sprocket and tire mount are protected by special covers.

If the fixing bolts are loosened, the tire begins to move or vibrate. If the tire is good, then the tension of the chain should be normal. After stretching, she will walk for at least five working days without braces. Therefore, you need to carefully tighten the bolts that hold the tire.

To understand how to tension a chain on a chainsaw, first you need find and lower the chain brake. The tension screw is located next to the tire; it is turned until the chain pulls on the tire. Then pull the chain in the clockwise direction. If it does not move, then it should be slightly loosened by turning the tension screw in the opposite direction.

Chain stretched

If your chain sags on a chainsaw, then this indicates a malfunction of some mechanism; one of the options is to wear the chain itself.

Over time, the metal is deformed and the chain becomes 0.5-1 cm longer. It is best to eliminate this problem by buying a new chain, but there is a way to get the old one back into operation. Experts say that it is very difficult and almost impossible, but we will tell you how it can be done at home.

For this we will need:

- vice;

- file;

- electric welding machine (not needed in all cases);

- hammer;

- pliers;

- little beard.

Normal chainsaw chains are made of solid steel, so it is difficult to disconnect. Disconnect the chain to the inside of the rivet, which serves as a connecting mechanism.

To begin with, the chain needs to be fixed in a vice, and then gradually grind out the protruding part. You need to grind down with a file or file. It is not recommended to use the grinder, as there is a risk of damaging the side parts of the links. After grinding rivets knocked out with a beard. Embossed rivet should not be thrown away. You may not be able to find a replacement.Manufacturers of gasoline saws do not produce individual parts for the chain, since they do not assume that consumers will be able to repair the chain themselves. To make a new rivet yourself, most likely you will fail, so you have to install the old one.

In order to shorten the chain, you need to divide it in two places. But remember, that the number of guides on the inner side of the chain and the distance between them must be combined with a leading sprocket.

After removing one or more links (depending on the degree of chain stretching), the chains can be connected. We connect to the old rivets, while tightly pressing them on the sides.

After removing one or more links (depending on the degree of chain stretching), the chains can be connected. We connect to the old rivets, while tightly pressing them on the sides.

Next we need a welding machine. Rivet need to weld to the side of the link. After this, we grind off the surplus, which was formed during welding. The chain can be considered again serviceable.

Badly fixed leading sprocket

One of the possible options sagging chain on your device - problem with leading asterisk. Most often, everything happens because the star is loose. Now we will tell you how to fasten the star correctly and then put the chain on the chainsaw.

First you need to remove the protective cover of the engine. Next, remove the protective cover candles, pull out the air filter. Then you need to unscrew the candle with a special key. In its place is put a special stopper that holds the piston in a certain position. Use a special key (you can use the universal key for the grinder) by rotating the clutch plate clockwise until the piston reaches the highest position. If you look into the hole of the candle, the piston should remain at the bottom. In the role of a stopper, you can use a thick rope, it is better to fold it several times. After fixing, you can clamp the sprocket by turning the clutch plate counterclockwise.

After clamping, you need to do everything in the reverse order, that is, collect a chainsaw.A tire is put on the tire; it must fall on the drive sprocket that holds it. The tire is placed in special holes for fastening and bolted. Then put protection.

How to stretch: setting the cutting element of the chainsaw

The main reasons for the sagging chain, we have dismantled. How to install the chain on a chainsaw, described in paragraph above. Now you need to properly tighten the chain, and check that it is not overtightened.

Chain tension

You can tighten the chain two ways: fast and frontal. It is best to stretch the front way.

If you carry out a frontal stretch, then you need to unscrew the nuts that hold the tire, and lift it over the edge. Special bolt on the right, you need to tighten the chain to obtain an acceptable stretch, and then lift the tire even higher and tighten it.

If you use the quick stretch method, you first need to raise the thumb nut handle and loosen it.Then tighten the chain tensioning screw clockwise until it stops. Then re-tighten the wing nut and lower the handle.

Stretch check

To check the chain tension, you need to turn off the saw brake system. Then manually hold the chain on the tire, if it runs smoothly and does not sag, then everything is fine. If the chain goes very tight, then it needs to be loosened a bit, because there is a risk of rupture during operation.

Operation Tips

Knowing how the chain is tightened on a chainsaw is not enough. You need to properly care for the saw, then you will extend the life of not only the chain, but the whole mechanism. Here are some operation tips:

- Clean the air filter regularly and lubricate it with oil. If necessary, replace the filter with a new one.

- Before starting work, always check that all nuts and bolts are tightly fastened so that the mechanism does not fail during operation.

- Regularly lubricate the bearings, and do not forget about cleaning candles from burnout.

- Lubricate the sprocket wheel. And after working with a chainsaw, do not forget to clean it.

- Lubricate, sharpen and tighten the chain is always on time, then there will be no problems with the tire and tenacious.

If you use all of the above tips, your device will last much longer than the warranty period.